Jun 20, 2025

In the wire and cable industry, plastic cable drum, as important auxiliary tools, play a crucial role in storage, transportation and wire laying. Its performance directly affects the quality and production efficiency of wires and cables. With the continuous advancement of materials science and manufacturing processes, plastic cable drums have been increasingly refined in design and functionality to meet the demands of various fields.

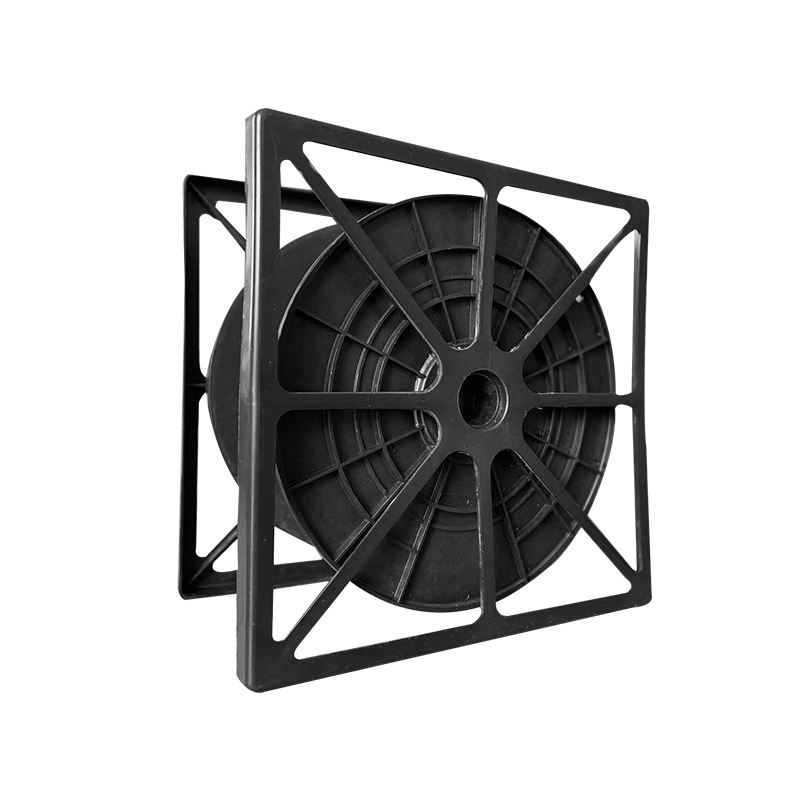

The structural composition of plastic cable drums

Side panels

The side panels are an important component of plastic cable drums and are usually located on both sides of the reels. It serves to support and protect the cables, preventing them from scattering or getting damaged during winding and transportation. The diameter of the side plate directly affects the winding capacity of the cable reel. A larger diameter of the side plate can accommodate longer cables. The material is generally made of high-strength plastics such as ABS and PP, which have good impact resistance and corrosion resistance, ensuring that the side panels can work stably in various environments. For instance, at some outdoor construction sites, cable reels need to withstand wind, sun and rain erosion. The side panels made of ABS material can effectively resist these harsh environmental factors, ensuring the service life of the cable reels.

(1) Cylinder

The cylinder is the middle part connecting the two side plates, and the cable is wound around the cylinder. The diameter and length of the cylinder determine the winding space and shape of the cable reel. It needs to have sufficient strength and stability to withstand the weight of the cable and the tension generated during winding. The surface of the cylinder is usually designed to be relatively smooth to reduce the friction of the cable during winding and laying, and to avoid damaging the outer sheath of the cable. Some high-end plastic cable drum bodies also adopt special processing techniques, such as adding anti-slip textures to further enhance the stability of cable winding and prevent cables from sliding on the body.

(3) Shaft hole

The shaft hole is located at the center of the cable reel and is used to connect with the laying equipment or transportation tools. The size and accuracy of the shaft hole are of vital importance. It must fit closely with the shaft of the matching equipment to ensure that the cable reel can rotate smoothly during the wire laying process without any shaking or eccentricity. In power engineering, the shaft holes of large cable reels are usually specially reinforced. Metal inserts or thickened plastic are used to enhance the load-bearing capacity and wear resistance of the shaft holes, so as to meet the long-term and high-load working requirements.

(4) Other components

In addition to the above-mentioned main components, some plastic cable drums are also equipped with auxiliary components such as traction holes and handles. The traction hole is used to insert ropes or tools when moving cable reels, facilitating manual or mechanical traction. The handle makes it convenient for the operator to manually rotate the cable reel to perform small-scale wire release or retraction operations. Although these components seem simple, they can greatly enhance the operational convenience and work efficiency of cable reels in practical use.

The characteristics of plastic cable drums

(1) Light in weight and easy to handle

One of the greatest advantages of plastic cable drums compared with traditional metal cable reels is their light weight. This enables operators to handle and move cable reels more easily at the installation, transportation and construction sites of cables. In some narrow Spaces or working scenarios where cable reels need to be moved frequently, the portability of plastic cable drums is particularly prominent. For instance, when laying wires in interior decoration, workers can easily move plastic cable drums to each room for wire laying operations, which greatly improves work efficiency and also reduces the labor intensity of workers.

It is corrosion-resistant and has a long service life

Plastic materials have excellent corrosion resistance and can resist the erosion of various chemical substances, such as acids, alkalis, salts, etc. This enables plastic cable drums to maintain good performance even in harsh environmental conditions, such as in chemical enterprises and coastal areas, and to be less prone to rust or damage. In contrast, metal cable reels are prone to corrosion in these environments, leading to a decline in structural strength and a shortened service life. The corrosion resistance of plastic cable drums enables them to work stably for a long time, reducing the frequency of replacement and maintenance and lowering the usage cost.

(3) Good insulation performance

In the fields of power and communication, the insulation performance of cable reels is of vital importance. Plastic itself is an excellent insulating material. plastic cable drums can effectively prevent current leakage and ensure the safety of operators and equipment. During the laying and use of high-voltage cables, the insulation performance of plastic cable drums can prevent safety accidents caused by cable leakage. For some communication cables that are sensitive to electromagnetic interference, the insulation properties of plastic cable drums can also reduce the interference of external electromagnetic signals on the transmission signals of the cables, ensuring the stability of communication quality.

(4) The cost is relatively low

In terms of manufacturing cost, plastic cable drums are usually less expensive than metal cable reels. Plastic materials are relatively inexpensive and their production processes are relatively simple, allowing for large-scale production. This makes plastic cable drums have a relatively high cost performance in the market and become the first choice for many enterprises. For some projects with limited budgets but requiring extensive use of cable reels, such as small-scale construction projects and rural power grid renovations, the low-cost advantage of plastic cable drums becomes more prominent. They can effectively control project costs while ensuring the usage effect.

The application fields of plastic cable drums

(1) Power industry

Cable laying: In the laying project of power cables, plastic cable drums are used for load-bearing and wire release. Whether it is the upgrading and transformation of urban power grids or the construction of rural power facilities, plastic cable drums are indispensable. When laying underground cables, the cable reels are placed on the cable laying frames. As the cables are laid, the cable reels rotate slowly to smoothly release the cables. The lightness and good rotational performance of plastic cable drums make the cable laying work more efficient and convenient.

Substation construction: A large number of cables are needed inside a substation to connect various electrical equipment. plastic cable drums are used for storing and transporting these cables. Their insulation performance can effectively prevent leakage accidents in the complex electrical environment of substations, ensuring the safe operation of substations. Meanwhile, the corrosion resistance of plastic cable drums can also adapt to the possible chemical substances and humid environment in substations.

(2) The communication industry

Optical cable laying: With the rapid development of 5G technology, the demand for laying communication optical cables is increasing day by day. plastic cable drums are widely used in the winding and laying processes of optical cables. Due to the high requirements for the bending radius and tension control of optical cables, the smooth surface and stable structure of plastic cable drums can ensure that the optical cables are not damaged during winding and laying, guaranteeing the stable transmission of communication signals. When laying optical cables in complex terrains such as mountainous areas and the wild, the portability of plastic cable drums enables construction workers to carry and operate them more conveniently.

Construction of communication base stations: The wiring inside communication base stations also requires the use of cable reels. The insulation performance of plastic cable drums can prevent signal interference and ensure smooth communication among various devices within the base station. Its corrosion resistance can adapt to various environments where the base station is located, such as high temperature, humidity, and dust, ensuring the stable performance of the cable reel during long-term use.

(3) Construction industry

Construction wiring: During the construction process of buildings, a large amount of wires and cables are needed for the installation of electrical systems. plastic cable drums are used for storing and providing the wires and cables required for construction. Its light weight and easy portability enable construction workers to conveniently carry out wiring work on each floor and in every room of the building. In the construction of high-rise buildings, workers can easily transport plastic cable drums to the required locations via elevators or stairs, thereby enhancing construction efficiency.

Interior decoration wiring: During interior decoration, in order to ensure the normal operation of various electrical equipment, meticulous wiring work is required. plastic cable drums can provide a neat and orderly supply of wires. Their surface is smooth and will not scratch the outer sheath of the wires, ensuring the quality and safety of the wires. Meanwhile, the appearance of plastic cable drums is usually simple and beautiful, and they are in harmony with the interior decoration environment.

How to choose the right plastic cable drum

(1) Select according to the cable specification

Cable diameter: The diameter of the cable is one of the important bases for choosing a cable reel. The diameters of the cable reel's cylinder and side plates should be large enough to ensure that the cables can be tightly and neatly wound around the reel, and that winding difficulties or deformation of the reel will not occur due to overly large cable diameters. For thicker cables, cable reels with larger cylinder diameters need to be selected. For thin cables, cable reels with relatively smaller cylinder diameters can be selected to improve space utilization.

Cable length: Select a cable reel with an appropriate winding capacity based on the length of the cable to be wound. The winding capacity of a cable reel is usually determined by the diameter of the side plates and the length of the cylinder. When calculating the winding capacity, the outer diameter of the cable and the number of winding layers need to be taken into consideration. Generally speaking, the larger the diameter of the side plate and the longer the length of the cylinder, the greater the winding capacity of the cable reel. In actual engineering, the specifications of cable reels should be reasonably selected based on the specific length requirements of the cables to avoid the need to replace cable reels multiple times due to insufficient winding capacity, which may affect work efficiency.

(2) Consider the usage environment

Outdoor environment: If the cable reel is to be used outdoors, its weather resistance and UV resistance need to be taken into consideration. Choose plastic cable drums with sun protection, water resistance and anti-aging functions to ensure that they can be used stably for a long time under harsh outdoor conditions such as direct sunlight and rain erosion, without deformation, fading or material aging. In salt spray environments such as by the seaside, it is also necessary to choose cable reels with stronger corrosion resistance.

Indoor environment: When used indoors, although the environmental conditions are relatively good, the coordination between the cable reel and the surrounding environment as well as the space occupation still need to be considered. For some places with high aesthetic requirements, such as shopping malls and office buildings, for interior decoration wiring, plastic cable drums with simple appearances and harmonious colors can be chosen. At the same time, according to the size of the indoor space, choose a cable reel of the appropriate size to avoid taking up too much space due to the cable reel being too large and affecting the indoor layout.

(3) Pay attention to quality and brand

Material quality: High-quality plastic cable drums are usually made of high-strength and environmentally friendly plastic materials. When making a choice, you can observe the appearance of the cable reel to check for any defects such as bubbles, cracks or deformations. You can also learn about the brand and performance parameters of the plastic materials used in the cable reels, such as tensile strength, impact strength, corrosion resistance, etc. High-quality materials can ensure that cable reels have good physical properties and a long service life.

Brand reputation: Choosing plastic cable drums from well-known brands is often more reliable. Well-known brands usually have strict production process standards and quality control systems, which can ensure the stability and reliability of product quality. Meanwhile, the brand's products have also become more complete in terms of after-sales service, such as providing product warranties and technical support. In the market, one can learn about the reputation and credibility of different brands of plastic cable drums by consulting product reviews, industry experts or other users, and thus make a wiser choice.

Maintenance and care of plastic cable drums

Regular inspection

Visual inspection: Regularly conduct visual inspections on plastic cable drums to check if there are any cracks, damages or deformations on the side panels and cylinders. If minor cracks are found, they can be repaired in time using plastic welding tools. For severely damaged or deformed cable reels, they should be replaced in time to avoid safety accidents during use. Check whether there is any wear or damage to the shaft holes, traction holes and other parts of the cable reel. If there are any problems, repair or replace the relevant components in time.

Inspection of rotating parts: Inspect the rotating parts of the cable reel, such as shafts and bearings, to ensure they rotate smoothly without jamming or abnormal noise. Regularly add lubricating oil to the rotating parts to reduce friction and extend their service life. When adding lubricating oil, a lubricant suitable for the plastic material should be selected to avoid using lubricating oil that is corrosive to the plastic.

(2) Cleaning and maintenance

Surface cleaning: Regularly wipe the surface of the plastic cable drum with a clean damp cloth to remove dust, dirt and debris. For stubborn stains that are difficult to clean, a mild cleaner can be used for cleaning, but it is necessary to avoid using cleaners containing strong acids, strong alkalis and other corrosive components to prevent damage to the plastic surface. After cleaning, the cable reels should be dried promptly to prevent water residue from causing plastic aging or rusting (if there are metal parts).

Internal cleaning: The interior of the cable reel, especially the interior of the cylinder, should also be cleaned regularly. Compressed air or a vacuum cleaner can be used to thoroughly remove the dust and debris inside to prevent these impurities from causing damage to the cables during the winding process. When cleaning the interior, it is necessary to pay attention to checking whether there are any foreign objects stuck between the cylinder or rotating parts. If so, they should be cleared in time.

(3) Store correctly

Storage environment: plastic cable drums should be stored in a dry, well-ventilated and cool place, avoiding direct sunlight and high-temperature environments. When exposed to sunlight or high-temperature environments for a long time, plastics are prone to aging and deformation, reducing their performance and service life. At the same time, avoid storing the cable reels in damp places to prevent the plastic from getting damp and moldy or the metal parts from rusting.

Storage method: Cable reels should be placed vertically to avoid horizontal stacking. Vertical placement can reduce the force on the side plates of the cable reel and the cylinder, preventing deformation due to long-term pressure. If stacking storage is required, it should be ensured that the number of stacking layers is not too large, and appropriate supports should be placed between each layer to disperse the pressure. During storage, it is necessary to avoid the cable reels being hit or squeezed by external forces to prevent damage.

Conclusion

plastic cable drums, with their unique structural design and excellent performance characteristics, play an indispensable role in multiple industries such as power, communication, and construction. The correct selection and use of plastic cable drums, along with proper maintenance and care, not only ensure the safe and efficient transportation and laying of wires and cables, but also extend the service life of the cable reels and reduce usage costs. With the continuous development of various industries, higher requirements have been put forward for the performance and quality of plastic cable drums. It is believed that in the future, plastic cable drums will keep making progress in material innovation, structural optimization and other aspects, providing more powerful support for the development of related industries.