Oct 11, 2025

Cable drums are essential tools in the storage, transportation, and deployment of cables. They are used in various industries including telecommunications, power distribution, and construction. Among the most common types are wooden and plastic cable drum. While both serve the same basic function of holding and organizing cables, they differ in material, durability, environmental impact, cost, and practical applications. Understanding these differences is crucial for businesses and professionals seeking the most suitable cable management solution.

The most obvious difference between plastic and wooden cable drums is the material. Wooden cable drums are typically made from treated timber or plywood. The drum consists of two circular end flanges connected by a cylindrical core. The wood provides a solid structure that can support heavy loads, and it is easy to customize on-site if needed.

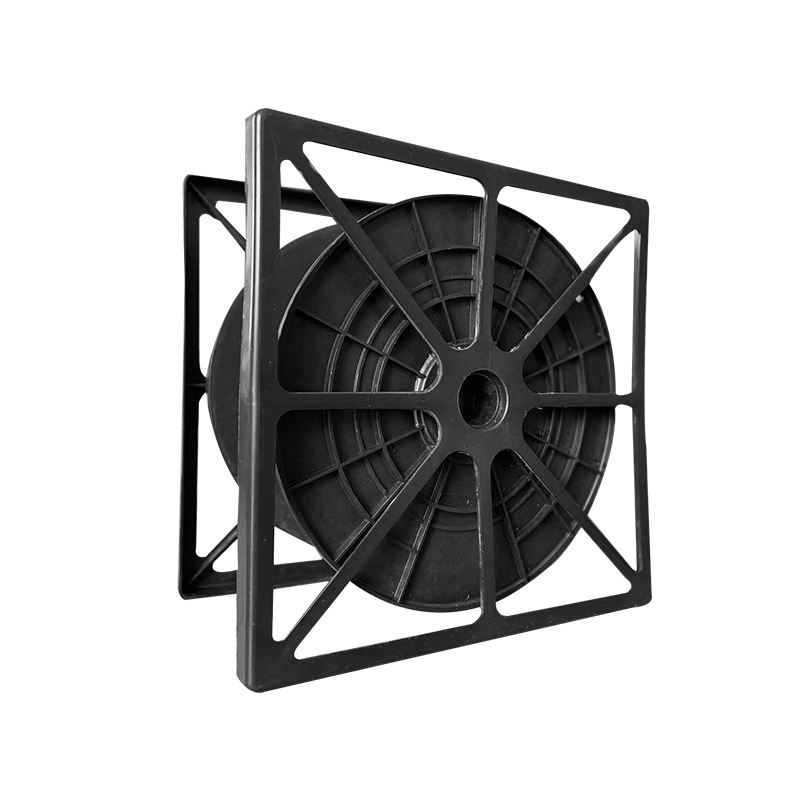

Plastic cable drums, on the other hand, are made from high-density polyethylene, polypropylene, or other durable polymers. These drums may be produced using injection molding or rotational molding techniques, resulting in a uniform and smooth surface. Plastic drums can be manufactured in various sizes and designs, including solid or hollow cores, and they often include reinforced ribs for additional strength.

Weight is an important consideration in selecting a cable drum. Wooden cable drums are generally heavier due to the density of the timber. This can make handling and transportation more challenging, especially for larger drums loaded with cable. Additional manpower or machinery such as forklifts may be required to move them safely.

Plastic cable drums are significantly lighter in comparison. Their reduced weight makes them easier to handle, transport, and install without specialized equipment. This can be particularly beneficial in environments where frequent movement of cables is required, such as temporary construction sites or outdoor installations.

Durability is a key factor when choosing between wooden and plastic cable drums. Wooden drums, while strong, are susceptible to moisture, rot, and insect damage. Prolonged exposure to rain or high humidity can weaken the wood, potentially leading to structural failure or cable damage. Wooden drums can also splinter or crack under impact.

Plastic cable drums are more resistant to environmental factors. They do not absorb water and are largely unaffected by moisture, chemicals, or UV exposure. This makes them suitable for outdoor storage and transportation, especially in regions with harsh weather conditions. Plastic drums are also less prone to cracking or splintering under impact, which improves safety during handling.

Load capacity is another consideration. Wooden drums have traditionally been favored for very heavy cables, as solid wood can support substantial weight. However, wooden drums can weaken over time if exposed to moisture or rough handling.

Plastic drums, depending on their design and material thickness, can also handle heavy loads. Modern plastic drums are often reinforced with ribbing or metal inserts to increase their structural strength. For medium to heavy cables, plastic drums provide a reliable alternative while offering better resistance to environmental degradation.

Wooden cable drums are often reused, but their lifespan can be limited. They may suffer from wear and tear during handling, and the wood can degrade over time, especially if stored outdoors. Many wooden drums are eventually recycled for other purposes, such as furniture or firewood.

Plastic cable drums are generally more reusable. Their resistance to moisture, chemicals, and mechanical wear allows them to be used multiple times without significant degradation. Properly maintained plastic drums can last for many years, making them a cost-effective solution in the long term, despite a potentially higher initial purchase price.

Environmental impact is increasingly important in industrial decisions. Wooden cable drums are made from natural resources, which are biodegradable. However, deforestation and the use of treated timber can have negative environmental consequences. Disposal of treated wood must be done carefully to avoid chemical contamination.

Plastic drums are made from synthetic polymers, which are non-biodegradable. However, many types of plastic drums are recyclable, and using recycled plastic reduces the environmental footprint. The durability and reusability of plastic drums also contribute to sustainability, as fewer drums are discarded over time compared to wooden alternatives.

Cost is often a deciding factor when choosing a cable drum. Wooden drums are usually less expensive initially because wood is widely available and manufacturing processes are simple. However, the long-term costs may increase if drums need frequent replacement due to environmental damage or wear.

Plastic drums may have a higher upfront cost due to the complexity of molding and material selection. However, their longevity, resistance to damage, and lighter weight can reduce overall costs related to transportation, handling, and replacement. Over time, plastic drums can provide a more cost-effective solution, especially for businesses that reuse drums frequently.

Safety is critical when handling cable drums. Wooden drums can splinter, and nails or metal fasteners may protrude, posing a risk to workers. Heavy wooden drums also increase the risk of injury during lifting or moving.

Plastic drums, with smooth surfaces and lighter weight, reduce the risk of splinters or sharp edges. Reinforced designs also prevent deformation or collapse during handling. This makes plastic drums a safer choice in many work environments, particularly where frequent manual handling is required.

Plastic drums are often easier to store and transport due to their uniform shape, stackable designs, and lighter weight. Some plastic drums can be nested or collapsed when empty, saving space during return transport. Wooden drums, in contrast, usually occupy more space and cannot be nested, making logistics less efficient.

In transportation over long distances, plastic drums reduce fuel consumption due to their lighter weight. Their resistance to moisture also prevents cable damage during transit, which is particularly important for sensitive fiber optic or electrical cables.

Both wooden and plastic cable drums are used in similar applications, but suitability varies depending on conditions. Wooden drums are suitable for heavy-duty industrial cables, temporary storage, and situations where cost constraints are significant. They are widely used in construction sites, power distribution projects, and shipping of heavy cables.

Plastic cable drums are suitable for repeated use, outdoor applications, sensitive cables, and environments where moisture or chemicals are a concern. They are also preferred in international shipping and situations where safety and efficiency in handling are priorities. The choice often depends on balancing cost, durability, environmental factors, and operational needs.

Plastic cable drums offer more flexibility in design and customization. They can be produced in different colors, sizes, and shapes to meet specific industry requirements. Features such as reinforced cores, ergonomic handles, and integrated spool systems can improve usability and efficiency.

Wooden drums can also be customized but require more labor-intensive processes. Custom sizes or designs may involve cutting, assembling, and treating the wood, which increases production time and cost.

While wooden and plastic cable drums both serve the purpose of storing and transporting cables, they differ in material, durability, weight, safety, cost, and environmental impact. Wooden drums remain a practical solution for heavy-duty, short-term applications where initial cost is a priority. Plastic drums offer longer lifespan, environmental resistance, safety benefits, and logistical advantages, making them suitable for repeated use and sensitive applications.

Choosing between wooden and plastic cable drums requires careful consideration of the operational environment, cable type, handling requirements, and long-term costs. Understanding the strengths and limitations of each type helps businesses make informed decisions that optimize efficiency, safety, and sustainability.

In summary, the decision is not about which drum is universally better but which is more suitable for specific use cases. Evaluating material, durability, cost, and environmental impact ensures that the chosen cable drum meets operational needs while maintaining safety and efficiency.